Our Capability

When it comes to complex machining, Iridium has experience and connections to produce a wide range of components, large and small, which are frequently required for downhole tools or related equipment.

Every new project we take on is evaluated for the most cost effective set up and cycle time, as well as optimal packing and logistics, to ensure your critical tolerances are achieved while lead times and landed costs are kept in check.

Deep Hole Drilling

Iridium is proud to support production of parts requiring deep hole drilling up to 10 feet in depth, and vertical and horizontal honing for special tools like safety valves.

Complex Machining

From complex geometries and eccentric machining to special coatings and pressure testing, no matter your need, we can support your design and make it happen.

Premium Fasteners

We can offer a wide range of custom hardware, including bolts, screws and nuts in performance alloys such as Nitronic, Inconel, and Monel ready for extreme conditions.

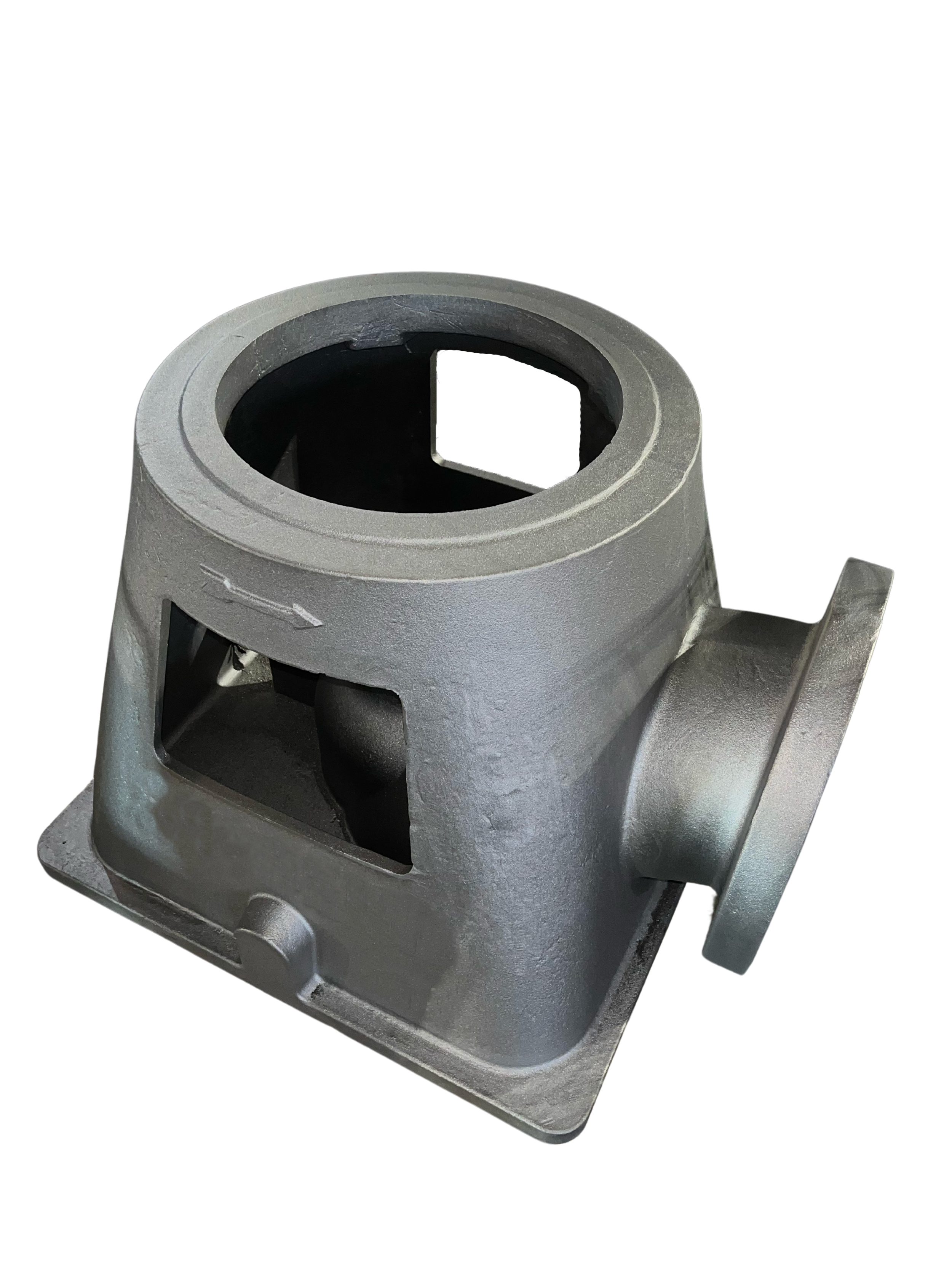

Large Castings

Complex castings can be costly to develop and troubleshoot. Our team has experience to work through large castings, saving on tooling and unit costs for long running and legacy parts.

Sound Like Your Parts?

Simplify your procurement process by partnering with us: your single-source solution for competitively priced parts, delivered with duties paid straight to your door.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!